The effects of the size of ceramic matrix grains and metal particles on mechanical and electrical properties of al 2 o 3 ti composites were investigated.

Resistivity ceramic matrix composites.

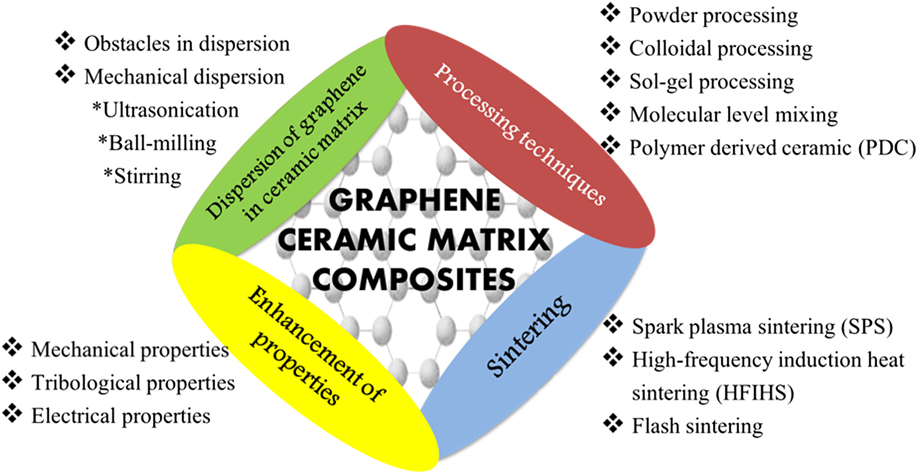

Pavol hvizdoš aleksandar vencl ceramic matrix composites with carbon nanophases.

Product description applications form matrix color nominal cure temp max.

This allows for detection mainly of fiber breakage by measuring the resistance change of the materials.

Development structure mechanical and tribological properties and electrical conductivity reference module in materials science and materials engineering 10 1016 b978 0 12 803581 8 11858 2 2021.

Dry operating temp.

In contrast for sic sic composites the resistivity of the matrix is on the same order of magnitude as that of the fibers.

Samples were fabricated using a hot press sintering method at 1400 c 1450 c 1500 c 1550 c and 1600 c from mixtures of al 2 o 3 and tih 2 powders.

Both the matrix and the fibers can consist of any ceramic material whereby carbon and carbon fibers can also be considered a ceramic material.

In such composites the fibers are the conductive material while the matrix acts as an insulator.

Ceramic matrix composites cmcs are a subgroup of composite materials as well as a subgroup of ceramics they consist of ceramic fibers embedded in a ceramic matrix.

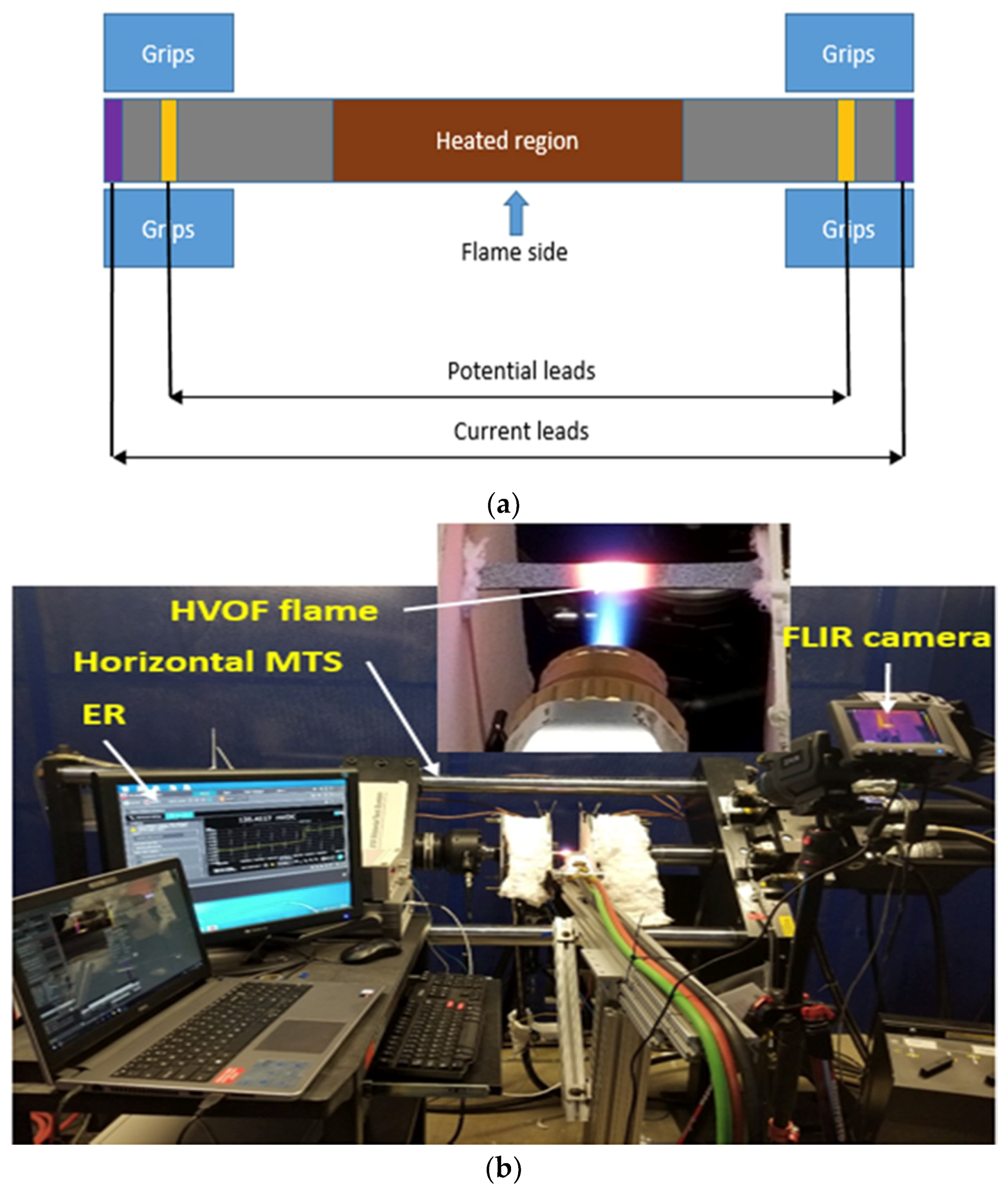

This work provides an indirect method for determining the out of plane electrical resistivity for composite materials while introducing the concept of length constant.

Ceramic matrix composites cmcs may be processed via conventional layup and curing techniques while only requiring a free standing high temperature sinter cycle to prepare them for high temperature use.

A study was conducted of the electrical properties of partially stabilized zirconia ceramic matrix composites with 0 to 40 vol of titanium niobium nickel and titanium and cristobalite over temperatures ranging from 25 to 800 c.